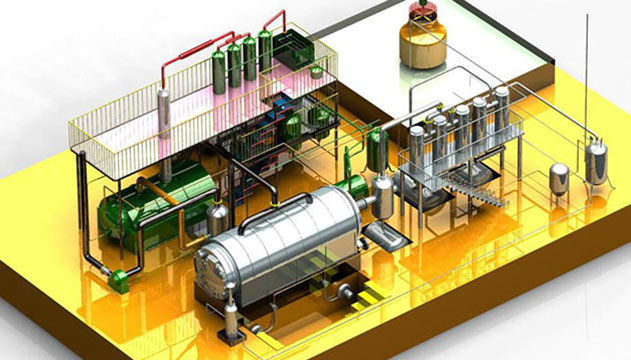

Pyrolysis Plant by Arslan Enginery Ltd.

It is clean Renewable Energy Source by which we can Recycle the Waste Tiers and Plastic into Fuel oil. By Pyrolysis Process we recycle and reuse the Waste Teri and plastic to black fuel oil and then we re-refine it to diesel by condensing gas into light fuel oils.

Arslan Enginery is having two different Pyrolysis Process.

1. Teri Pyrolysis Plant

2. Plastic Pyrolysis Plant

Firstly we go with Pyrolysis reaction in presence of catalytic and absent of oxygen at a reaction temperature of 350+ Degree with vacuum pressure , After condensing the gas to we get light fuel oil the remain black carbon will be used as a coal .

We offer continuous and Batch process .

Technical Details & Scope of Supply:

Our scope of supply includes Designing, Detailed Engineering, Procurement, Fabrication,

Supply, Supervision of Erection and Commissioning of plant suitable to meet the plant

capacities & Supply of below listed items:

1 Pyrolysis Reactor

2 Burner

3 Burner block and burner mounting assembly

4 Gas solid separator

5 Condenser

6 Oil Hold up tank

7 Gas scrubbing system

8 Cooling Tower

9 Oil Transfer pump

10 Cooling Tower circulation pump

11 Feed control valve

12 Feed conveyor

13 Internal scrapper

14 Scrapper gear box with mounting assembly

15 Scrapper motor ( flame proof)

16 Double mechanical seal

17 Plastic Shredding Machine

18 Main electrical panel with PLC system

19 Temperature Transmitter

20 Pressure transmitter

21 Temperature Guage

22 Pressure Gauge

23 Vacuum Pump System (Automatic)

26 Diesel tank for burner

27 Valves ( MS + SS) Set

28 Insulation

29 Field Cabling ( Instrument + Electrical ) Set

30 Piping Set

31 MS skid with epoxy painted Set

For Quotation please submit your raw martial details, per day capacity and plant Location.