Everyone hopes to find a usefulness for waste products, such that nothing really goes to waste at all. In this article, Arslan Enginery will like to broaden your smile with the Waste oil, Used oil, Motor oil Recycling re refining Plant Process.

The Black, Waste or Used Lube Oil or Motor Oil are then said to be used or contaminated type of automotive lube oil and industrial used oil. Waste Oil is simply waste oil, any petroleum or synthetic oil that has already finished its work in the engine it was used to lubricate. Used Lube Oil is defined as the petroleum-derived or synthetic oil which remains after the application of Lube Oil in lubrication, cutting purposes, etc. Lube Oil has a lot of usefulness for our machines, not just cars but other machines such as lawnmowers, and many others. It becomes Waste or Used Oil after it has been used, a time when elements (impurities) such as water, metal scrapings, dirt etc., must have been mixed with it. The build-up of temperature degrades the lubricating oil, thus leading to the reduction in properties such as; Viscosity, Specific Gravity, etc. As a result, the waste/used lube oil doesn’t perform as well as the virgin motor oil. Hence, such Waste Oil is replaced with New Lube Oil or re-refined oil, and that ends the work of the now waste used oil in most cases.

Used Motor Oil or Waste Lube Oil can really be useless and toxic. A drop of Used lube oil can contaminate thousands and thousands of gallons of water.

- It sticks to metals,

- It is slow to degrade,

- It is the major ingredient of oil contamination of waterways and

- It ends up polluting sources of drinking water.

This suggests that it must be properly disposed of because it has more harmful possibilities than usefulness when unrefined, What if it can be re-refined, recycled and made fit for re-use? Awesome yeah? Before I go into the Waste Oil Plant Process, let me differentiate between the three oil types. Not assuming if you do or do not know it all, the three types of oil are VIRGIN OIL, RECYCLED OIL AND RE-REFINED OIL.

As the name connotes, VIRGIN OIL is simply virgin oil i.e. it is crude oil that has never been used since it has passed through the refining process. It is the most used, and it sets the standard for oil quality generally.

RECYCLED OIL is simply used oil that has passed through a filtration system (maybe a Used Oil Recycling Plant) to remove any and every insoluble impurity. It does not go back to being pure again, and this is because the impurities removed does not include chemical contaminants. It can however be re-used.

RE REFINED OIL is recycled oil that goes through more processes, removing both soluble and insoluble impurities. It goes through the same distillation stack that is used in making virgin oil so that the water molecules and other contaminants are removed. It could be rated as the same base oil standard as the virgin oil if API qualifies it. This is what our Used Oil Recycling Plant does.

Did you see that? Re-refined Oil becomes the same as Virgin Oil; meaning it can be re-used!

Arslan Enginery is basically expert and richly experienced in Used Oil Recycling/Re-Refining Or Motor Oil Recycling Engineering Mechanism & also provides investment to projects in the form of plant machinery & technology CAPEX in various regions like Africa, Saudi Arabia, UAE, Central asia, North and South America for more info submit the project report after evaluating the project we can plan the investment package.

PROCESS OFFERED BY ARSLAN ENGINERY FOR USED AND WASTE OIL RECYCLING Re refining technology by modern refinery of crude oil .

Arslan Enginery Private Limited Company is an esteemed company based in India & USA. We offer technical solutions and projects related primarily to oil & gas processing. We are involved in setting up TurnKey projects overseas, Designing, Engineering, Supply & Installation and Construction of quality and efficient Plants and Projects. We wish to create pollution minimized atmosphere by following our mission of protecting nature with innovative ideas for Recycling Waste and Used Lube Oil, through our Waste Oil Recycling Plants.

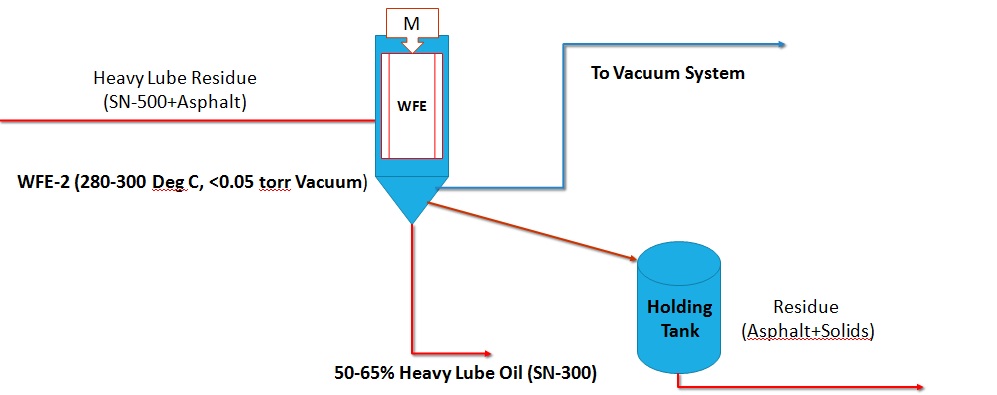

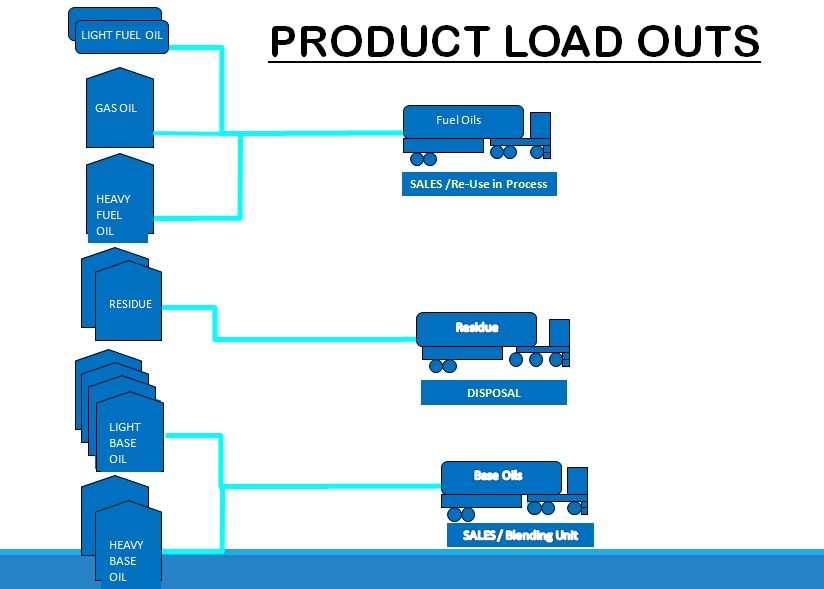

We make use of the Wiped Film Evaporator (WFE), a Short path distillation, followed by Solvent extraction or Mild Hydrofining finishing process involved for the recycling (Re-refining) of Used/Waste Lube Oil to Base Oil group I, group II and group II+ with zero environmental waste; no air, no solid and no liquid pollution. Perfect! The WFE is ideally suited to process hard-to-handle, heat sensitive and viscous materials. These are just some of the many and varied products that the WFE processes. It is designed to carry out deodorization, distilling, concentration, reboiling, solvent recovery and stripping, then re-refined oil is ready for lube oil blending stage.

Arslan Enginery offers tailor-made designs & technology for Waste Lube oil projects, Our Turnkey project provisions include:

- Basic & Detailed Engineering.

- Procurement of all equipment.

- Construction and Erection of complete project.